How To Select The Perfect Agricultural Gearbox For Heavy-Duty Applications

2025-11-27

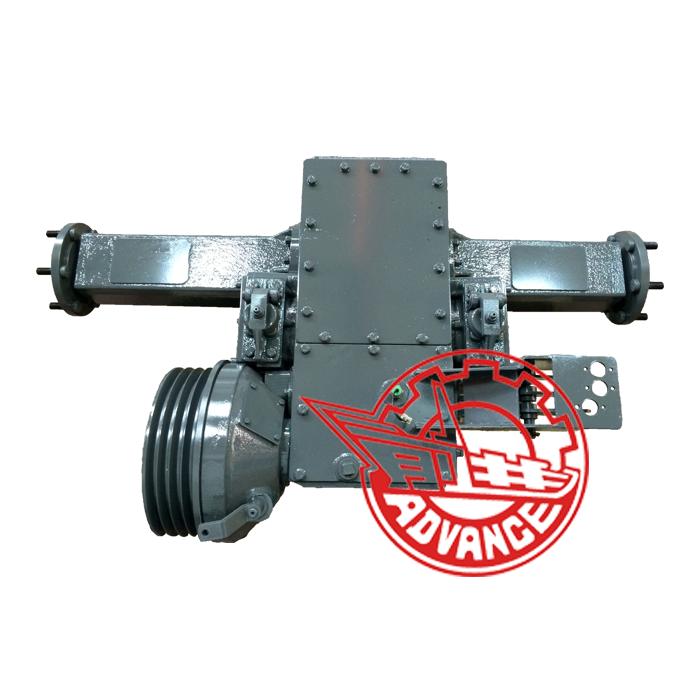

Choosing the right Agricultural Gearbox is critical for the productivity and longevity of your heavy-duty farming equipment. A mismatch can lead to costly downtime and repairs. At Cagon, we engineer robust power transmission solutions built to withstand the most demanding applications, from deep tilling to large-scale harvesting. This guide will help you navigate the key selection criteria to ensure maximum performance and reliability for your operation.

Selecting the perfect heavy-duty Agricultural Gearbox involves evaluating several technical parameters against your specific operational requirements.

Key Parameters to Consider:

-

Horsepower (HP) and Torque Rating: The gearbox must be rated to handle the input power from your tractor and the output torque required by the implement. Exceeding these ratings risks catastrophic failure.

-

Gear Ratio: This determines the output speed relative to the input speed. Select a ratio that provides the optimal working speed for your implement (e.g., a rotary cutter needs a high RPM).

-

Input Shaft Configuration: Consider the type (e.g., 1-3/8” 6-spline or 1-3/4” 20-spline) and rotation direction to ensure compatibility with your power take-off (PTO).

-

Construction Materials: For heavy-duty use, look for hardened alloy steel gears and high-strength, cast-iron housings for superior durability and impact resistance.

-

Sealing and Lubrication: Effective sealing systems are vital to prevent contaminant ingress. Many Cagon gearboxes feature advanced lip seals and are pre-filled with high-temperature grease for long service life.

The following table compares two common Cagon series for heavy-duty tasks:

| Feature | Cagon HD-Series | Cagon XT-Series |

|---|---|---|

| Best For | Primary tillage (Heavy-duty rotary cutters, tillers) | Extreme applications (Sugar cane harvesters, forage wagons) |

| Max Torque | Up to 1,200 lb-ft | Up to 2,000 lb-ft |

| Housing Material | High-Grade Cast Iron | Reinforced Ductile Iron |

| Gear Material | Case-Hardened Alloy Steel | Carburized and Hardened Alloy Steel |

| Standard Seal | Double-Lip Rubber Seals | Labyrinth Seals with Grease Purge |

Agricultural Gearbox FAQ

What is the expected service life of a heavy-duty Agricultural Gearbox?

With proper installation, correct lubrication, and operation within its specified limits, a high-quality Cagon Agricultural Gearbox can last for thousands of operational hours. The service life is highly dependent on avoiding shock loads and maintaining a strict maintenance schedule.

Can I use a standard gearbox for a heavy-duty application?

It is not recommended. Standard gearboxes are not designed to handle the high torque, shock loads, and continuous operation of heavy-duty tasks. Using one will lead to premature failure, potential damage to other equipment, and safety hazards. Always choose a gearbox rated for your specific duty class.

How often should I check the lubricant in my Cagon gearbox?

For heavy-duty applications, we recommend a visual inspection before each use. A complete lubricant check and change should be performed after the first 50 hours of operation (break-in period) and then every 250 hours or at the end of a season, whichever comes first. Always refer to the specific Cagon product manual.

Making the correct choice in a heavy-duty Agricultural Gearbox protects your investment and ensures your farm runs smoothly during critical seasons. The robust engineering and precise specifications of a Cagon gearbox provide the reliability you need.

Contact us today to speak with our technical experts. We will help you select the perfect Cagon Agricultural Gearbox for your specific equipment and operational challenges.